Industrial Control and Automation Laboratories

Index of the laboratories

- Industrial Control and Automation Laboratory

- Automatic Control Laboratory

- Industrial Informatics Laboratory

- Automation and Industrial Robotics Laboratory

Industrial Control and Automation Laboratory

Location

A5.7

Description

A facility shared by all the School's bachelor's degrees. It has eight workspaces for groups of two students.

Subjects

Equipment

Each of the workspaces is equipped with a PC installed with the Siemens TIA Portal and a teaching module based on the PLC s7-1200 by the same manufacturer.

Automatic Control Laboratory

Location

A5.6

Description

Laboratory in which practicals for the automatic control subjects are held. It has six workspaces for groups of two students.

Subjects

- Automatic Regulation.

- Control Techniques.

- Advanced Control .

- Control of Energy Systems.

- Process Control.

Equipment

All the workspaces are equipped with a PC running MATLAB, an oscilloscope and a teaching temperature control model based on the commercial Omron E5AK PID regulator.

In addition, the Laboratory has three commercial teaching models for controlling the position and speed of an engine (model ALECOP MV541) and three models for controlling the level/flow of a liquid in a tank (model ALECOP MD544).

Industrial Informatics Laboratory

Location

A5.5

Description

Laboratory in which practicals for the industrial informatics subjects and subjects related to the implementation of control systems are held. It has seven workspaces for groups of two students.

Subjects

- Information Systems and Industrial Communication.

- Integration of Automatic Systems.

- Immplementation of Automatic Control System.

- Telecommunications and Internet.

Equipment

Each workspace is equipped with a PC, electronic instrumentation (function generator, power supply and oscilloscope) and a kit for programming microcontrollers based on the AT89C5131A microcontroller.

Automation and Industrial Robotics Laboratory

Location

Situado en A5.4

Description

Laboratory in which practicals for the automation and industrial robotics subjects are held. It has six workspaces for groups of two students.

Subjects

Equipment

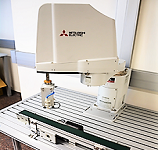

Each workspace has a PC and an Allen-Bradley CompactLogix L16ER PLC. In addition, the Laboratory is equipped with a flexible manufacturing system and two material handling robots. The flexible manufacturing system is an SMC FAS200 system that implements an assembly process and is made up of six stations equipped with Allen-Bradley MicroLogix 1400 PLCs. The two material handling robots are a small, articulated Mitsubishi RV-2AJ robot and a SCARA RH-3FH5515 robot, also by Mitsubishi.

Share: